Process requirements for lithium battery

The air humidity must be accurately controlled in the process where lithium batteries are manufactured in the workshop. The water vapor, like a catalyst, reduces the quality and performance and shortens the shelf life of the metal lithium batteries exposed to humid environment. The sealing and injection processes in the process of lithium battery production are extremely sensitive to the moisture in the air in the workshop. Once the excessive moisture in the air is absorbed by the battery, many problems, such as bulges and leaks, will be caused. Therefore, production workshop must have controllable air humidity value.

With the development of the society, lithium battery has been more and more important and has been more and more widely used. In the process of lithium battery production, the cell and shell in injection process have been dried, thus they are extremely sensitive to the moisture in the air in the workshop. Once the excessive moisture in the air is absorbed by the battery, many problems, such as bulges and leaks, will be caused. Therefore, the limited environmental control of lithium battery injection process is a crucial link in the production process of lithium battery.

Importance of Humidity for Lithium Battery

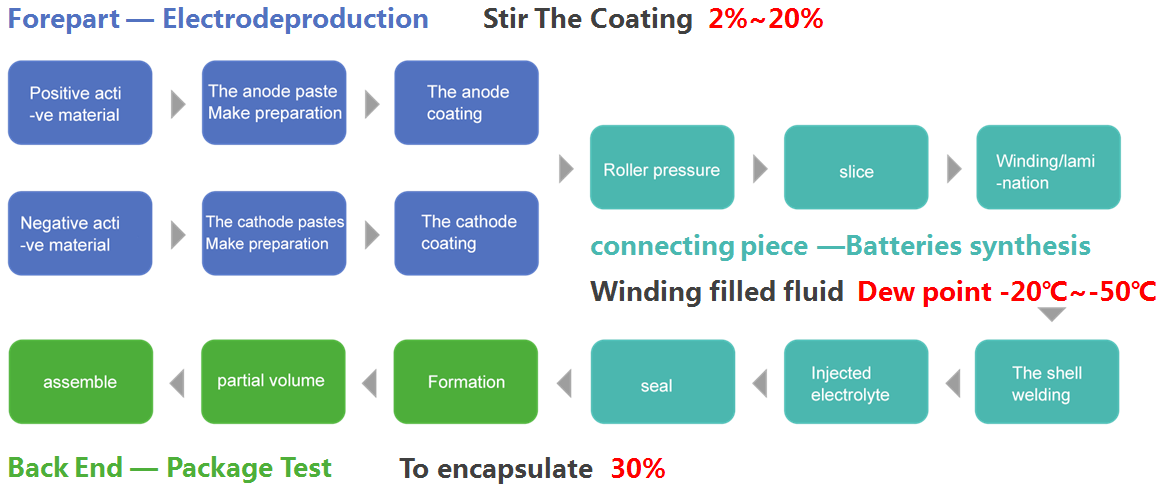

Lithium battery and thermal battery are very sensitive to air humidity in the production process; the materials used in some processes have a strong water absorption. Once the excessive moisture in the air is absorbed by the battery, many problems, such as bulges and leaks, will be caused. Therefore, the humidity control in the production environment for lithium battery is a crucial link. In the process of current manufacturing, the dew point in the controlled environment in the production workshop of lithium-ion battery manufacturer should generally be -35℃~-40℃. Besides, there are a large number of workers on the battery production line, the moisture emitted by them must be promptly eliminated with dry gas. Therefore, the gas with a dew point accurately controlled within -50℃~ -60℃ should be used for continuous purging of the production area. The typical production process flow of a battery plant is as follows:

Polder's Solutions

Polder rotary dehumidification unit adopts the efficient silica gel wheel and efficient molecular sieve wheel of domestic and international well-known brands. These wheels are specially synthesized into a hygroscopic agent which is embedded into the fiberglass matrix. Since the wheel has tiny porosity and high heat resistance, it is suitable for low dew point conditions or treating the air containing volatile organic compounds, such as ethylene glycol and acetaldehyde. The regeneration air up to 220℃ can be used for the wheel, thus the wheel basically will not polymerize. Therefore, it also has high performance and will not have any loss of hygroscopic agent. The wheel may reach -60℃D.P. according to airflow conditions.

Temperature and humidity control parameters for all links of lithium battery production

Monitorable, storable and traceable