Polder Environmental Science& Technology is a professional manufacturer of adsorbing rotary dehumidifier, based on users’ requirements, designs functional sections individually, and satisfies air-conditioning requirements such as air volume, outlet air temperature, outlet air humidity and outlet air cleanness. Meanwhile, relevant patented technologies of Polder Environmental Protection Science& Technology combine the philosophy of greenness, energy saving and environmental protection, apply thermal recycling technology, make the regeneration process more energy-saving, and the optimized body structure and high-performance thermal insulation materials minimize heat losses and save operation costs.

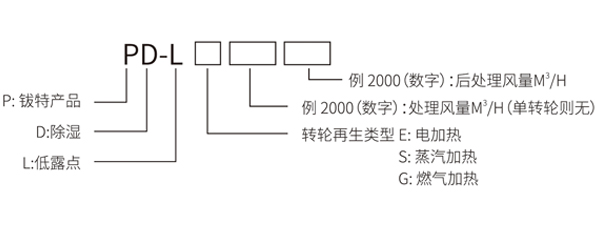

Notes To Models

Application Features

① Initial filter section: plate G4 or bag filter is used

② Front surface cooling/front preheating section: the cold medium of the front surface cooling can be frozen water or direct evaporation. Conventional pre-cooling design dew point range is 10℃-18℃; Under special working conditions, the front cold dew point can be designed to be about 7℃ ~ 10℃; Pre-heating can be performed with hot water, steam or electric heaters

③ Regenerative fan section: direct centrifugal fan

④ a return air mixing section: generally a mixture of fresh air and a return air

⑤ Runner dehumidification section: adsorption silicone runner and runner frame; Runner drive device; Runner seal system; Runner detection device

⑥ Regenerative heating section: regenerative heater (electricity/steam/natural gas/energy storage heat recovery)

⑦ Regenerative filter section: plate G4 or bag filter

⑧ Processing fan section: belt driven centrifugal fan/no volute fan

⑨ Post-surface cooling/post-heating section: the post-surface cold coil is generally dry cold coil, using chilled water or direct evaporation type; The rear heater can be in the form of hot water, steam or electric heating

⑩ Optional section: humidification section (electrode/dry steam/electric heat/wet film); Ozone generator section; PM2.5 fresh air purification treatment section; Oil filter section; Heat recovery section (plate heat recovery/runner heat recovery); Electrostatic dust removal sterilization section; Other specific design according to customer requirements Mixed air section: Generally, dry air is mixed with return air Steel structure foundation: high strength, convenient transportation, lifting, moving in place

Technical Features

1、modular design, according to the different needs of customers, choose different modules to achieve precise control of temperature, humidity, cleanliness and so on;

2、the complete unit includes efficient silica gel compound molecular sieve adsorption runner, air supply main fan, air purification filter, regenerative heater with temperature regulation, regenerative exhaust fan, precise temperature control of refrigeration/heating parts and other functional segments, intelligent control system;

3、the equipment frame adopts the whole steel plate welded structure, high strength, good sealing, export dew point control range -70;

4、the equipment insulation panel and frame structure can meet the strict standards of the industry, the unit insulation box board can be selected in stainless steel/steel spray panel + rubber plastic cotton/rock wool insulation, the internal panel material can be selected according to user needs, to meet the most stringent health and structural requirements;

5、the patented design of the runner sealing system, Polder special sealing device to ensure the air tightness of the wind system and anti-cold bridge function, reduce renewable energy consumption, improve the stability and reliability of the runner dehumidification;

6、Polder core components are imported parts, strict requirements for each part, such as regenerative fan using high-quality direct fan, high temperature resistance and corrosion resistance; At the same time, if the regeneration uses electric heating, it can be adjusted without poles to achieve energy saving in winter and transition season;

7、efficient and simple operation control system, with intelligent control program, to achieve a very user-friendly operation mode, and can be remote control according to user needs, and remote "diagnosis" function, to bring users more convenient and efficient service;

8、the main parts of the Polder equipment can be removed from the unit for cleaning or maintenance, and a number of alarm display functions are used in the control, such as filter blocking alarm, motor overload, current overload, high temperature protection and other fault display, which can quickly find the fault point and solve the problem quickly;

9、 can be equipped with direct expansion cold source, to achieve "one-stop turnkey project" service.

Scope Of Application

1、 The process and production process with strict requirements for temperature and humidity (low dew point)

Such as: lithium-sodium ion batteries, thermal batteries and other battery production workshops, medicine, food and other powder products production and gas transmission process

2、A variety of moisture sensitive items storage

Such as: lithium metal, battery raw materials, various chemical raw materials that are easy to absorb moisture, PET injection particles and so on

3、Scientific research laboratories, especially those engaged in high-tech biological, aerospace and electronic laboratories

For example, it is necessary to simulate various extreme environmental conditions in the experiment

4、Prevent condensation of low-temperature air conditioning and ice blockage of air duct